Reliable technology and quality

Our special processes are accredited by Nadcap

Those our technology and process assurance help to maintain at the high level of process repeatability, and thanks for them, we are rated high by our customers.

Those special processes required high quality and process reliability such as NDT, Anodizing, paint and shot peening process are our part of services.

In IAC Malaysia, in order to maintain process repeatability and reliability, we periodically conduct Nadcap Audit.

And our quality management system comply with EN9100 (AS9100/JIS9100 ) requirements.

Work Contents

Vapor degreasing

Equipped with timer, temperature control sensor, cooling.

system corresponding to environmental requirements

|

Vapor degreasing tank capacity |

18.4ft(length) x 3.0ft(width) x 5.9ft(depth) |

|---|---|

|

Maximum load on Tank |

0.5t |

Metal Cleaning

Transfer between tanks by semi-automatic carrier.

Alkaline cleaning, Alkaline or Acid etching, and desmutting

are performed before penetrant inspection.

|

Processing tank capacity |

18.0ft(length) x 2.5ft(width) x 4.9ft(depth) *A Tank in State of the art equipped with timer, temperature control sensor. |

|---|

Penetrant Inspection

| Apply water to remove penetrant liquid from part surface. |

| Product inspection are carried out under UV light in Penetrant inspection booth. |

Anodized

The latest rectifier with a built-in recorder is used to record our process parameters

| Anodizing treatment | Chromic acid anodized Sulfuric acid anodized Boric & Sulfuric acid anodized |

|---|---|

| Tank capacity | 18.0ft(length) x 2.5ft(width) x 4.9ft(depth) |

Painting

Compatible with all type of painting(Epoxy primer, High solid epoxy primer, Tank primer, Polyurethane top coat, etc.).

Spray Booth: Water curtain and gravity suction system booth

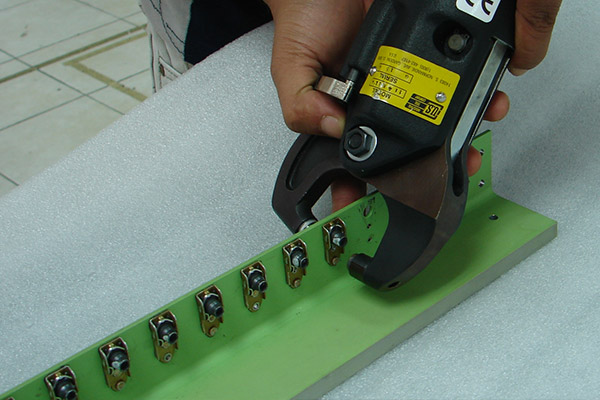

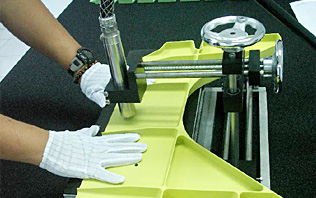

Identification

Using the identification equipment (ink-jet type), the product is clearly identified.